Written by David Stallings, head of Roaster and Importer Relations

As an industry, the term “coffee processing” refers to how we remove the seeds from a coffee fruit. How any given coffee is processed is important because of the fact that processing can have a strong impact on the flavors found in the finished cup of brewed coffee.

Though we colloquially refer to coffee as “beans,” this is botanically inaccurate. Coffee is the seed of a fruit. To be more exact, the coffee fruit is a drupe or stone fruit. Unlike other stone fruits, such as peaches or cherries, which possess relatively large mesocarps (the pulp or edible portion of these fruits), the coffee fruit possesses an incredibly small mesocarp. This means that the coffee fruit is not particularly well-suited to being eaten (by humans or even most animals). Through the ages we have, of course, found an equally pleasurable use for this fruit: coffee seeds are removed from the fruit, after which they are roasted, ground, and brewed into the decoction known as coffee.

Coffee Processing

We can talk about two broad categories of coffee processing: coffees that are pulped prior to drying and coffees that are not pulped prior to drying. Here, “Pulping” refers to removing the leathery skin of the coffee fruit, along with some fruit mucilage.

Regardless of the method used to separate the seeds from the coffee fruit (i.e. regardless of how the coffee is processed), it is critical that the coffee seeds be dried. As with many produce items, coffee seeds that have not been adequately dried could develop mold. Further, proper drying is critical for retaining the freshness of the coffee for the longest possible period of time. If a coffee is not properly dried, it could taste “old” (papery, woody) much faster than if the coffee was dried properly. As such, and interestingly enough, the terms “age” and “old” are fairly relative in coffee and have more to do with how a coffee is tasting, as opposed to how long it has been since the coffee was harvested. A coffee that is three months off harvest can taste “old” if it was not dried properly, while a coffee twelve months off harvest can still taste quite fresh.

Natural Processing

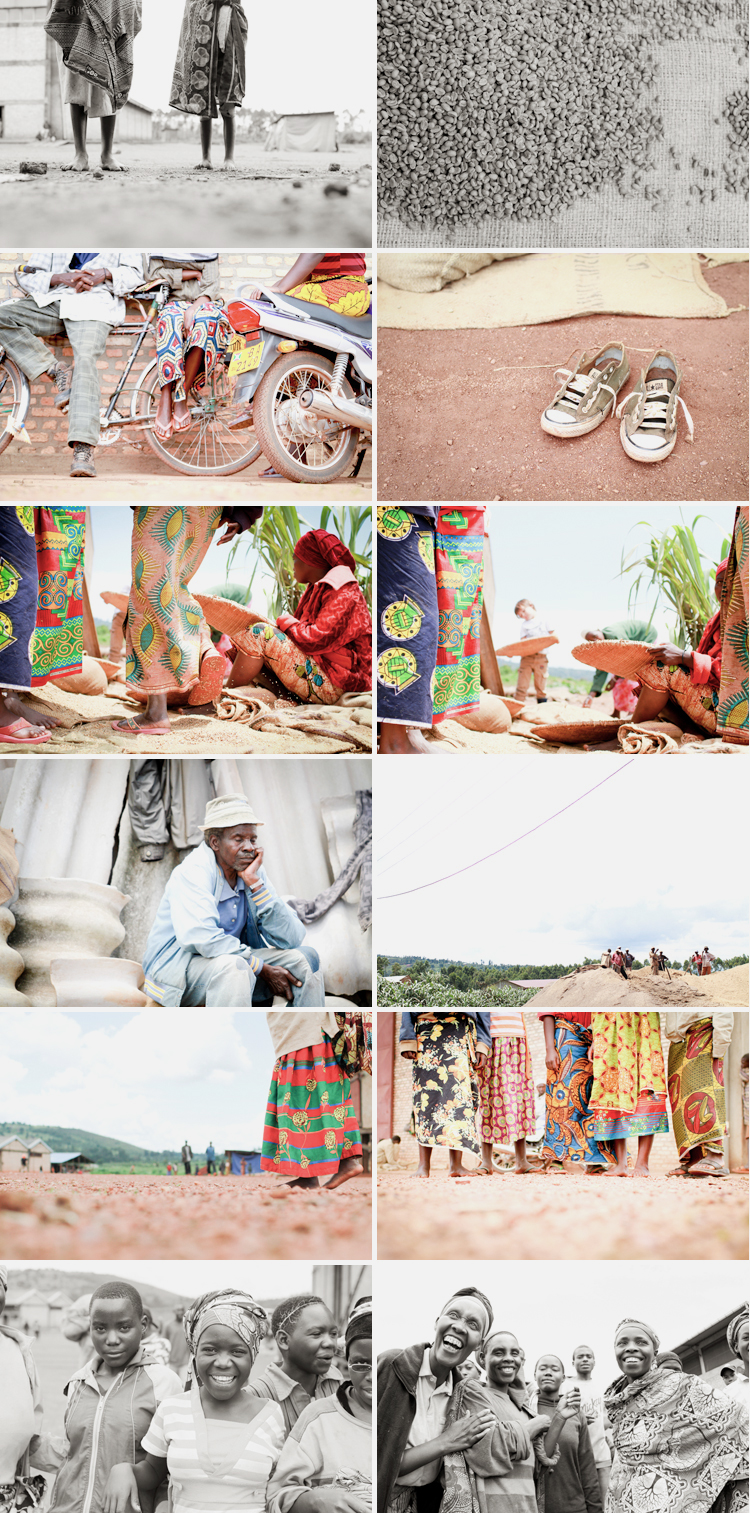

Coffees that are not pulped prior to being dried are typically referred to as Naturally Processed or Dry Processed coffees. To produce a Naturally Processed coffee, which happens to be the original processing method (due to its innate simplicity), one simply harvests the (ideally ripe) coffee cherries and dries the entire fruit. The coffee then remains on drying tables until the target moisture content is reached.

During this time the coffee fruit is turned at regular intervals to ensure even drying and to avoid any pockets of moisture from remaining that could encourage microbial proliferation. Naturally Processed coffees tend to be very fruit-forward and sweet, generally with lower perceived acidity. The distinctly fruity flavor profile of these coffees tends to be polarizing: some people absolutely love the character while others find it off-putting. Though ostensibly simple, producing clean Naturally Processed coffees is incredibly challenging. We wrote about that fact in this Instagram post back in November of 2020.

Fully Washed Processing

Coffees that are pulped prior to being dried can fall into two primary categories: Fully Washed and Honey. Fully Washed – also known as Washed, or Wet Processed – is the older and more popular of these two processing methods and involves pulping the fruit and then placing the mucilage covered seeds into a tank and allowing the mass to ferment. The fermentation taking place is dependent upon microbes found in the air and on the coffee plant consuming the sugars of the coffee fruit.

Yeasts and bacteria break down the sugars of the mucilage and the stubborn pectin layer immediately surrounding the seeds. After these layers are broken down, the mucilage is easily washed away and the coffee seeds, still covered in a protective parchment layer, are sent to drying tables to be dried to the target moisture-level. Fully Washed coffees tend to be clean, balanced, and present a sparkling acidity that can drive and inform the perceived sweetness in the finished cup.

Honey Processing

Existing somewhere between Fully Washed processing and Natural processing, the Honey processing method (also referred to as Pulped Natural) was developed by coffee equipment manufacturer Pinhalense in the 1990’s. The goal was to produce a coffee that struck a balance between the sweet, heavy-bodied character of a Naturally Processed coffee and the balanced cleanliness of a Fully Washed Coffee.

Honey processed lots begin by being pulped, like a Fully Washed process coffee. After pulping, however, the coffees skip tank-fermentation and mucilage removal and head directly to the drying tables, mucilage and all. A bonus of this processing is the small amount of water used when compared to Fully Washed coffees. We wrote about Honey Processed lots in an Instagram post back in November of 2020. That post can be found here.

When produced carefully, Honey processed lots can be very clean and elegant. In our experience, however, they can also lack both the fruited complexity of a Naturally processed coffee and the expressive acidity of a Fully Washed coffee. Over the past two years we have experimented with various ways to produce Honeys that remain clean but are also more expressive. We will share more about those processes in an upcoming blog post!

Why is it that sometimes the words just won’t come out? Is it because of the trouble that I sometimes have when I try to see past the bridge of my nose? They do say that when your vision is impaired it can effect your speech. For some anyway, obviously not everybody. Or is it because the words get all trapped up in a big cheesecloth in the sky and, even though I can smell them ripening, they just never make it down to me?

Why is it that sometimes the words just won’t come out? Is it because of the trouble that I sometimes have when I try to see past the bridge of my nose? They do say that when your vision is impaired it can effect your speech. For some anyway, obviously not everybody. Or is it because the words get all trapped up in a big cheesecloth in the sky and, even though I can smell them ripening, they just never make it down to me?